The competition called for entries of wearable 3D printed fashion pieces that were water inspired and had a sustainable agenda. The 3D print was meant to be a conversation piece about the opportunities presented by 3D printing technology in the fashion world.

The competition was organised in conjunction with the launch of NTU’s $30 million Additive Manufacturing Centre which will house state-of-the-art 3D printers.

Kaei Woei and Low comment on the inspiration for their deasign,

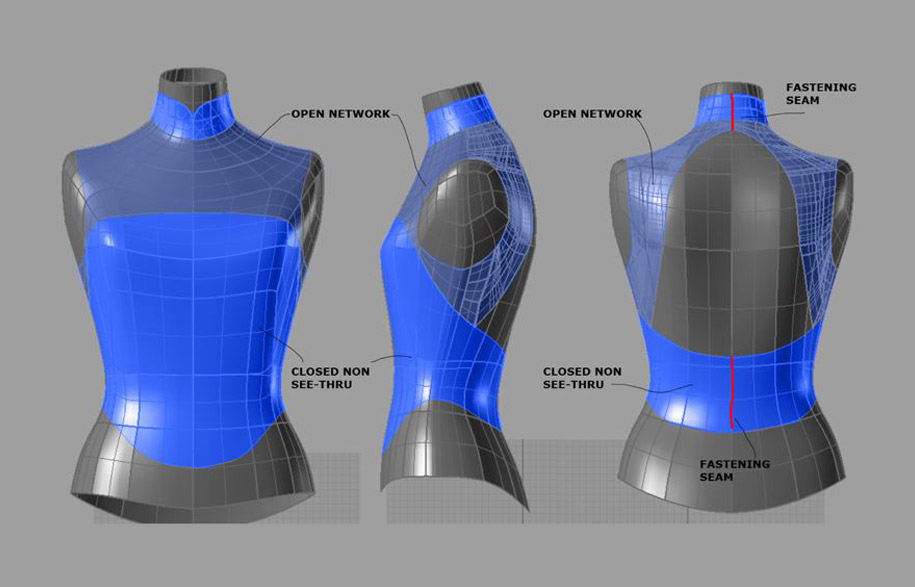

“While researching on water technologies and sustainability, we were compelled by an image of the electrolysis of water to create hydrogen. Focusing on the water molecules’ transient change of state, we express this in the design with a series of solid and “open” spheres.

“The network of “open” spheres created a lace-like fabric, which created a contrast between the solid and transparent pieces. At a micro level, stillness is embodied by the ripple-like patterns, which has a texture that alludes to a traditional textile weave.

“The silhouette of the design echoes a traditional Chinese cheongsam, creating an intriguing dialogue between tradition and technology.”

The final fashion piece was made up of 26 different sections and took approximately 170 hours to print in Flexible PLA. (Polylactic Acid). A version was also created comprising of only five parts for printing on a large format 3D Printer, allowing one to streamline its production.

“We wanted to showcase how disruptive 3D printing has become,” the duo state, “and how it has empowered the end user. We had challenged ourselves to create the design on a simple desktop 3D printer and the experience has proven to us that you don’t require access to an expensive large 3D printer to create unique wearable pieces. Merely using highly accessible domestic 3D printers we were able to create a fashion piece that reflected our vision.

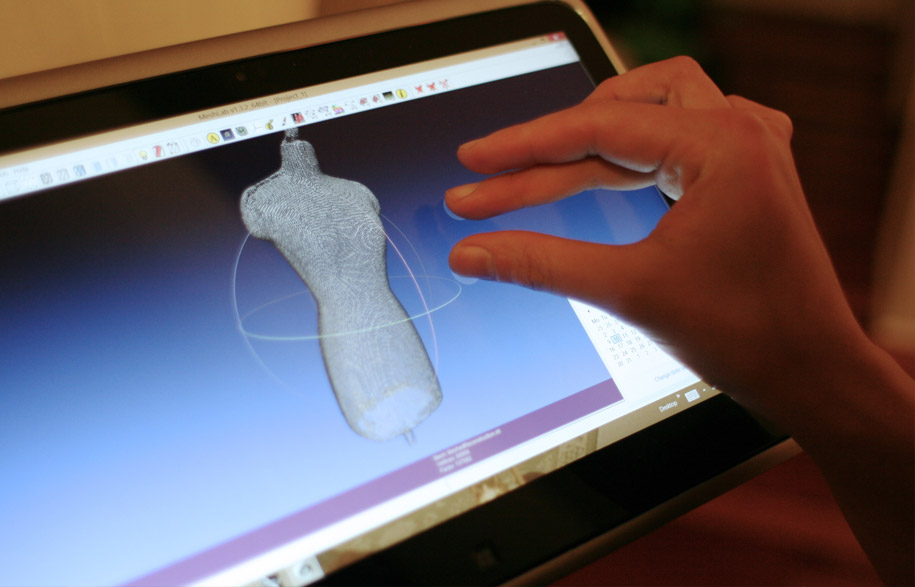

“We started the design process by creating a 3D scan of a tailor’s mannequin. By connecting a Kinect Sensor to our laptop, we were able to create a 3-dimensional point cloud of the object which was then processed to produce a 3-dimensional mesh from which we based our geometries.

“Using the Rhino 3D modelling software, we mapped out patterns of the

model’s much like a traditional tailor would. The model “skin” was then

“unrolled” and sized to be able to print within the constraints of our

3D printer.”

XYZ Workshop

xyzworkshop.com